Maintenance is an essential aspect in regards to the functioning of the business with dedicated tools. Whether it’s software solutions or equipment used for the manufacturing operations, or even if it’s the company's infrastructure, proper and timely Maintenance Should be conducted to ensure that they are long-lasting. Moreover, The proper Maintenance will ensure that there are hurdles that the company faces due to the internal equipment, software, or company assets. In every organization, there is a dedicated Maintenance team or multiple teams that will overlook the company's various Maintenance aspects.

There are two kinds of Maintenance directives: Preventive Maintenance and Corrective Maintenance, which will improve the company assets. No company can function by performing either of them. It's a collective approach where both Maintenance operations are conducted to ensure that all aspects of the company are running smoothly. Let's now move on to understand what is Corrective as Preventive Maintenance.

Corrective Maintenance

The Maintenance operations are conducted on equipment or a solution when an error occurs. Moreover, this is the repair done when a machine stops working or depicts results. Moreover, these are instantaneous Maintenance operations based on the need.

Preventive Maintenance

The Maintenance operations counted repentance between intervals to ensure that the functions of the machinery and the solution will not stop and interpret the company's operations. In addition, Preventive Maintenance is conducted during a respective interval that the manufacturer or the service provider has defined. This maintenance can also be undertaken when the company should be done for holidays or is not functioning, ensuring that the machines are running full-fledged with maximum productivity when it's back up.

The business will need dedicated tools that support maintenance management as it is an integral part required in the company's functioning. The Odoo platform and complete business management Enterprise and Resource Planning solution support the aspects of managing the company's operations with a dedicated Maintenance module. Both the Corrective as well as Preventive Maintenance can be conducted with ease in the Odoo Maintenance module. Moreover, most of the business needs to be detailed with the company maintenance aspects on its equipment, software solutions, assets, and the business infrastructure.

Odoo is the all-in-one business solution with dedicated modules of operations providing complete Maintenance to every business. With the modular structure, the company will have dedicated modules that support the business's functions, which are all manageable under one roof as each module is interconnected. This will allow for the autonomous management of the business operations and effectively control each aspect of the functions.

This blog will provide insight into Managing Equipment Maintenance with the Odoo platform.

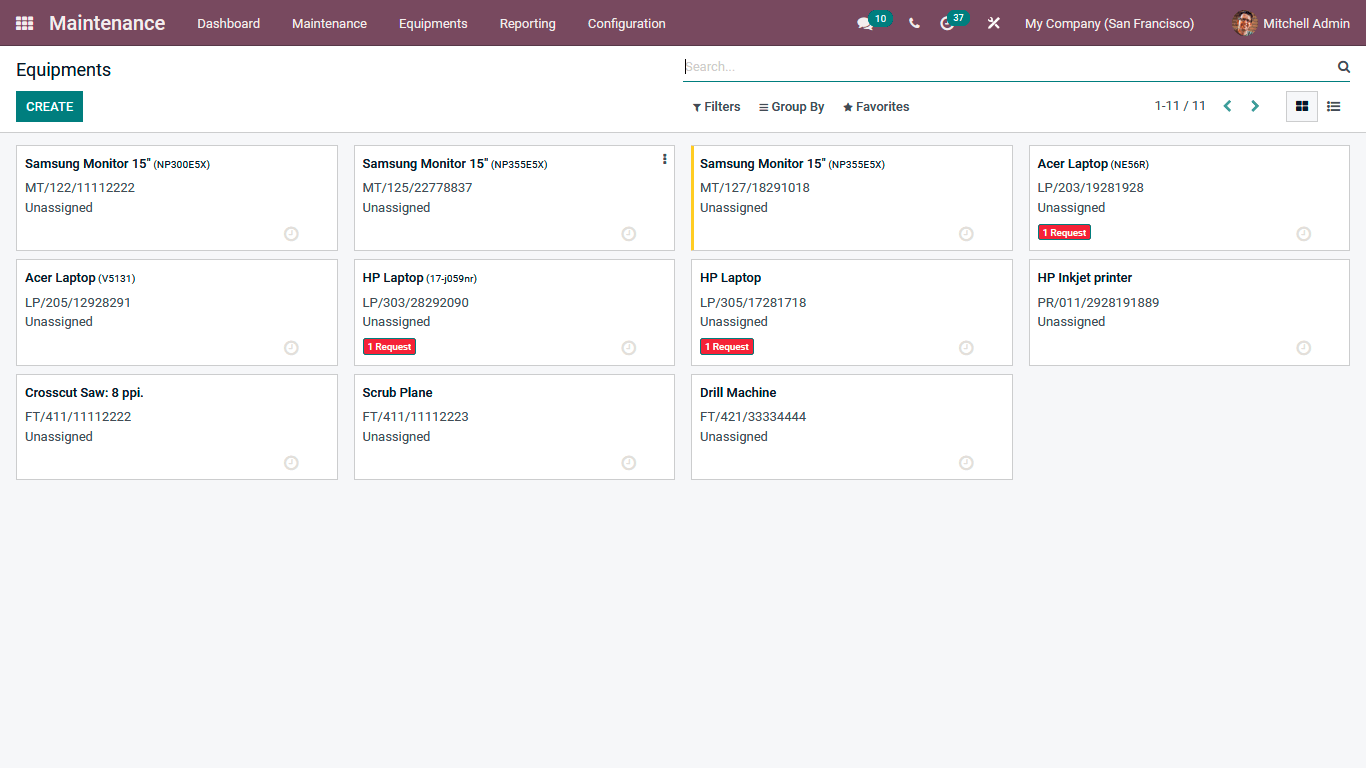

The Maintenance module of the Odoo platform has a dashboard where the maintenance requests of operations will be displayed in teams of functions. You can select the Equipment of Maintenance from the Equipment menu as depicted in the following screenshots. Here the Equipment will be defined. Filtering and Grouping tools are available to help you find the right equipment.

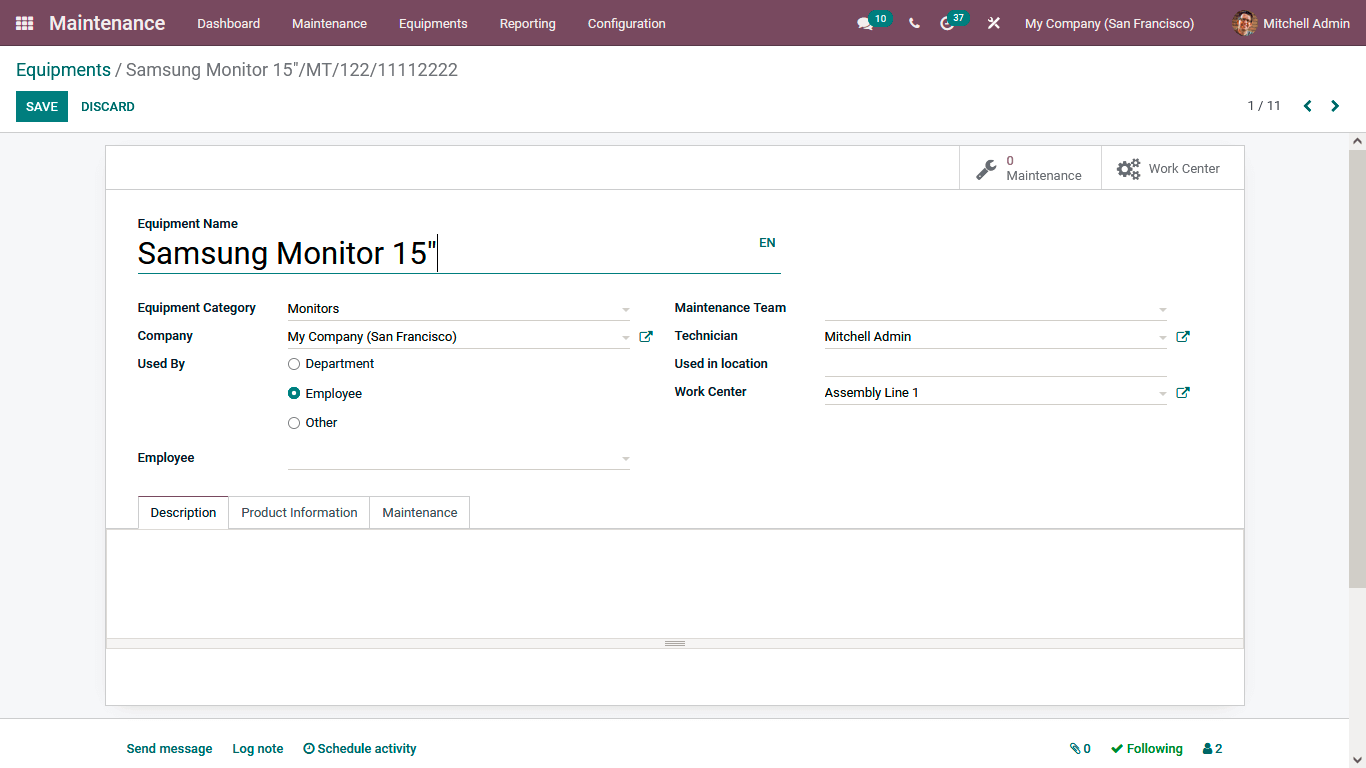

Upon selecting an Equipment that has been defined, you will be depicted with all the details regarding it. Here the Equipment Name, Equipment Category, Company, and the Used by aspects will be defined as Employee, Department, or Other aspects of the business operation. If it’s allocated to an Employee, the name should be described in the respective section. In addition, the Maintenance Team and the Technician earmarked for the separate Equipment will be described. Furthermore, the Used in Location and Work Center details will be defined.

Further, the Equipment description concerning the Maintenance aspects can be defined under the Description tab.

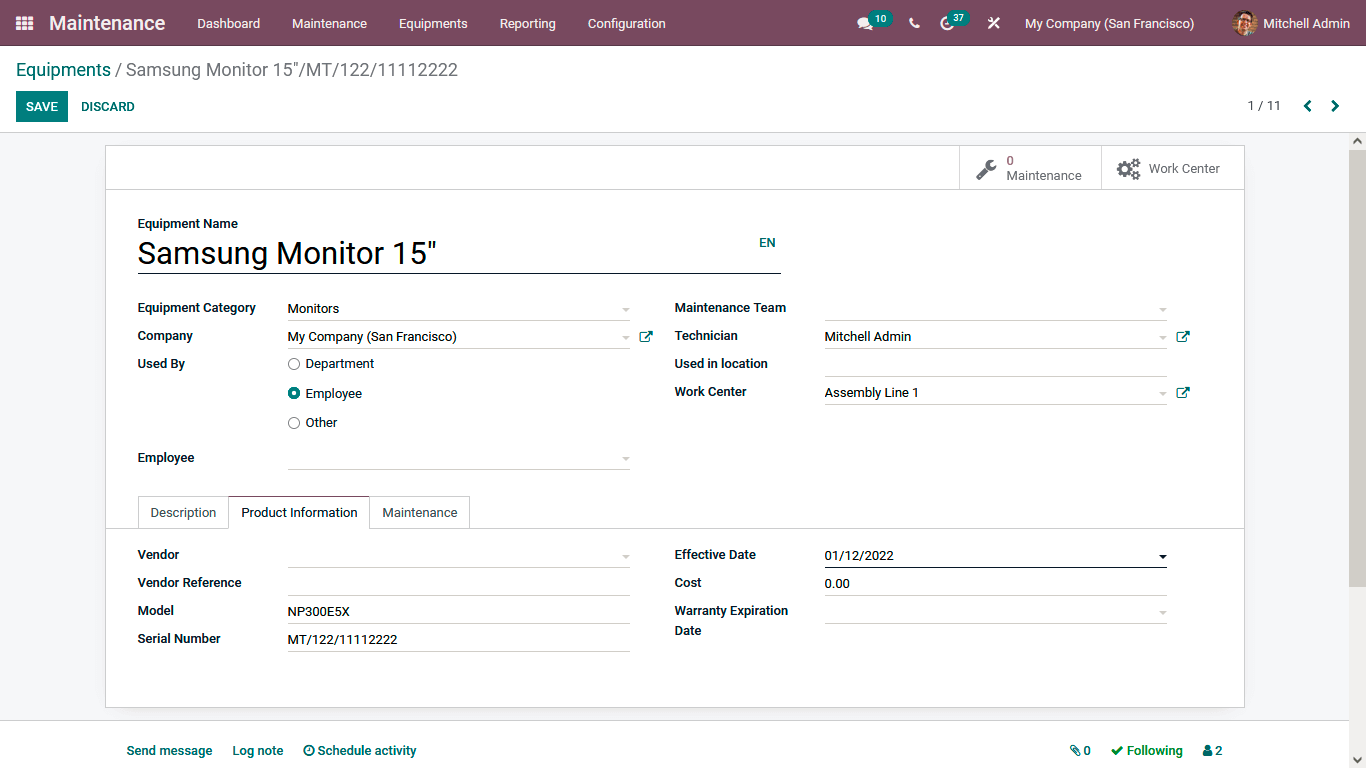

Under the Product Information, the Vendor details and the Vendor Reference, Model, and the Serial Number should be defined. Additionally, the effective Date, Cost, and Warranty Expiration Date can be determined.

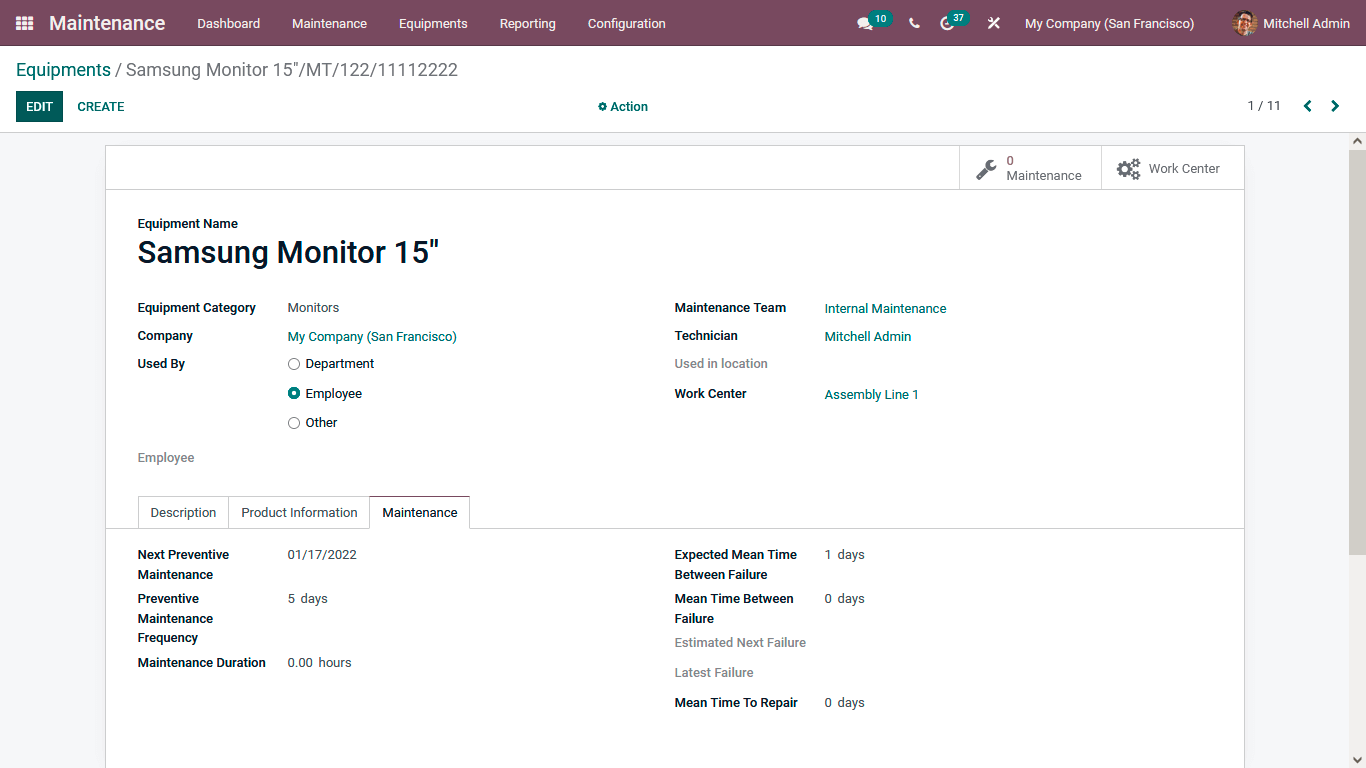

Under the Maintenance tab, the Next Preventive Maintenance Date and the Preventive Maintenance Frequency should be defined. Upon the description of the Preventive Maintenance aspects, the next Preventive Maintenance will be auto-scheduled based on the Frequency, which has been determined. Moreover, the Frequency will be calculated from the date specified in the Odoo platform. In addition, the Maintenance Duration and the Expected Mean Time Between Failure should be defined in days, and the estimated subsequent Failure and the Latest Failure should be limited. Moreover, the Mean Time to Repair should be little.

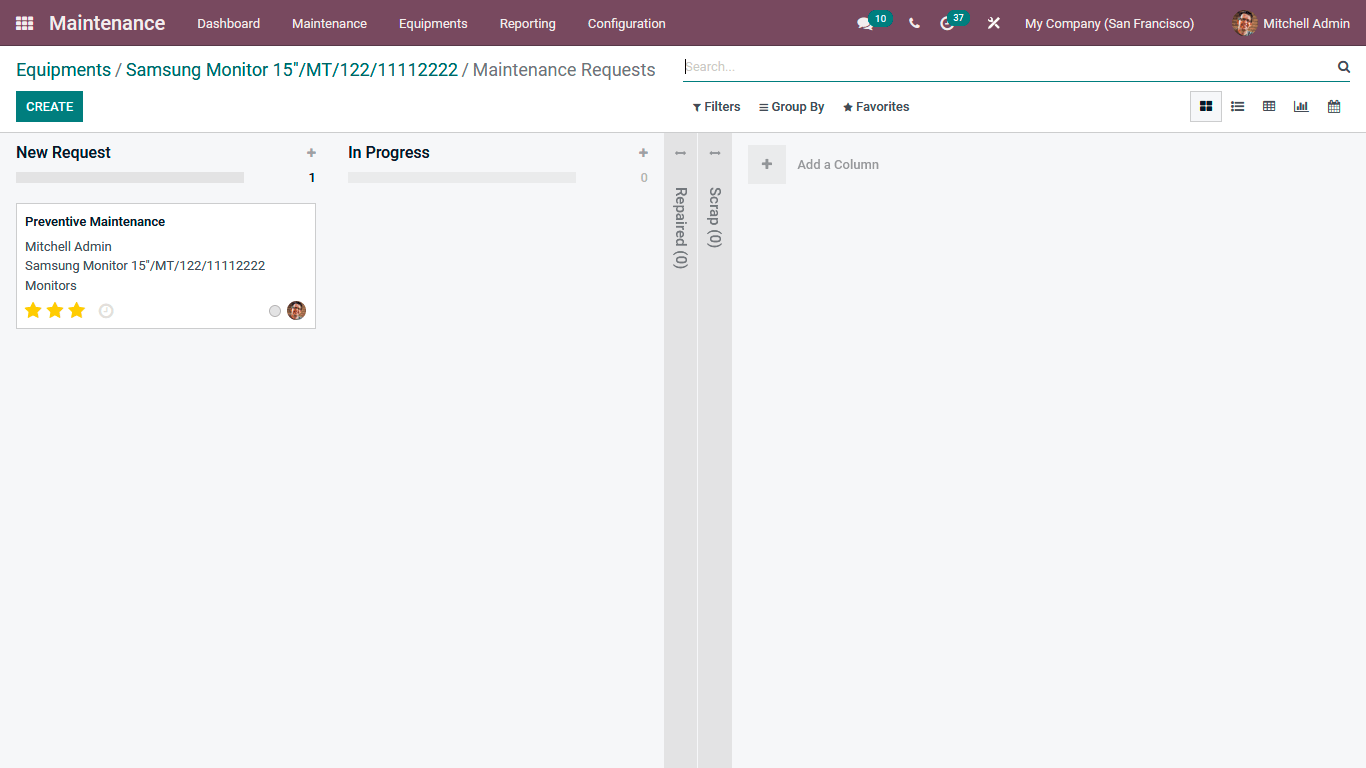

There will be an intelligent tab of Maintenance available, which can be chosen to understand the Equipment Maintenance aspects of operation, which will be defined as depicted in the following screenshot. Here the stages of the Maintenance operation on the Equipment described will be shown, and once the maintenance aspects are conducted the Stages of a respective process are changed automatically.

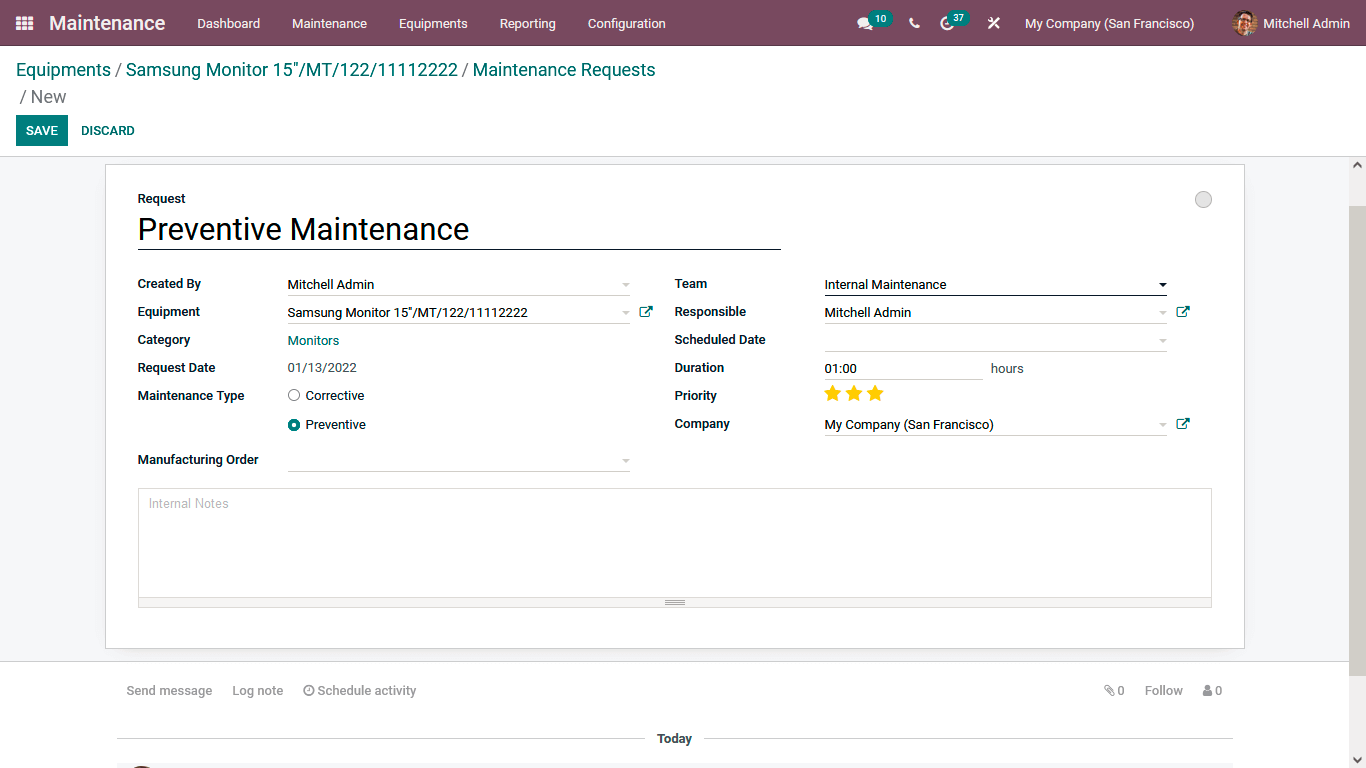

Upon entering, the respective Maintenance defined as the product is defined under the Preventive M, where the next Maintenance is calculated based on the Maintenance Frequency defined under the Product. The Request Name, Created By, Equipment, Category, Request Date, and the Mintainenece Type will be described here. A Preventive Maintenance is chosen as a case of it being a Corrective Maintenance; the Maintenance type will be defined as it.

Further, the Maintenance team, Responsible Person, Scheduled Date, Duration, Priority, and the Company details will be defined. The Manufacturing Order and the Internal Notes will be described in the Maintenance order as depicted in the following screenshot.

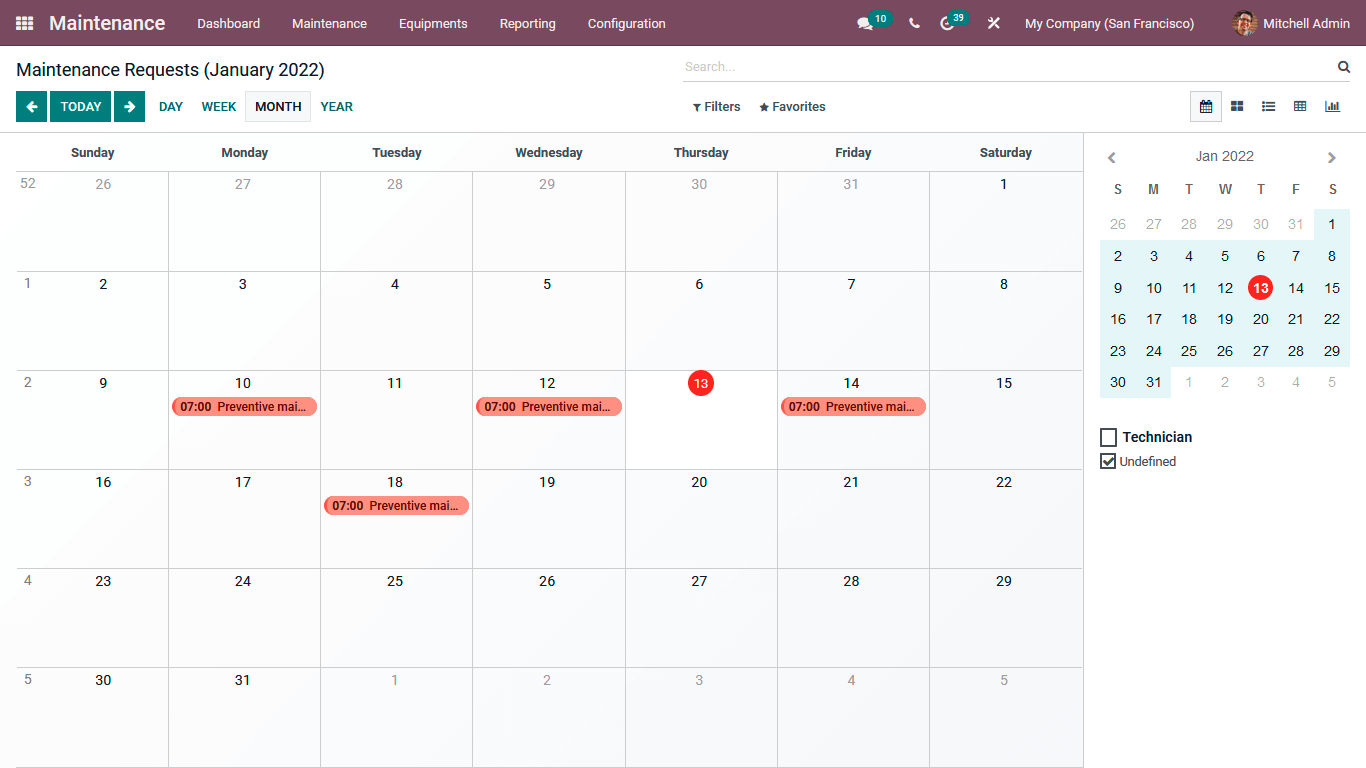

Once the Maintenance request has been defined, you can Save it further by selecting the Calendar view option, which is available. You will be able to view all the Maintenance requests defined. The Calendar View can be viewed in the form of Day, Week, Month, and Year.

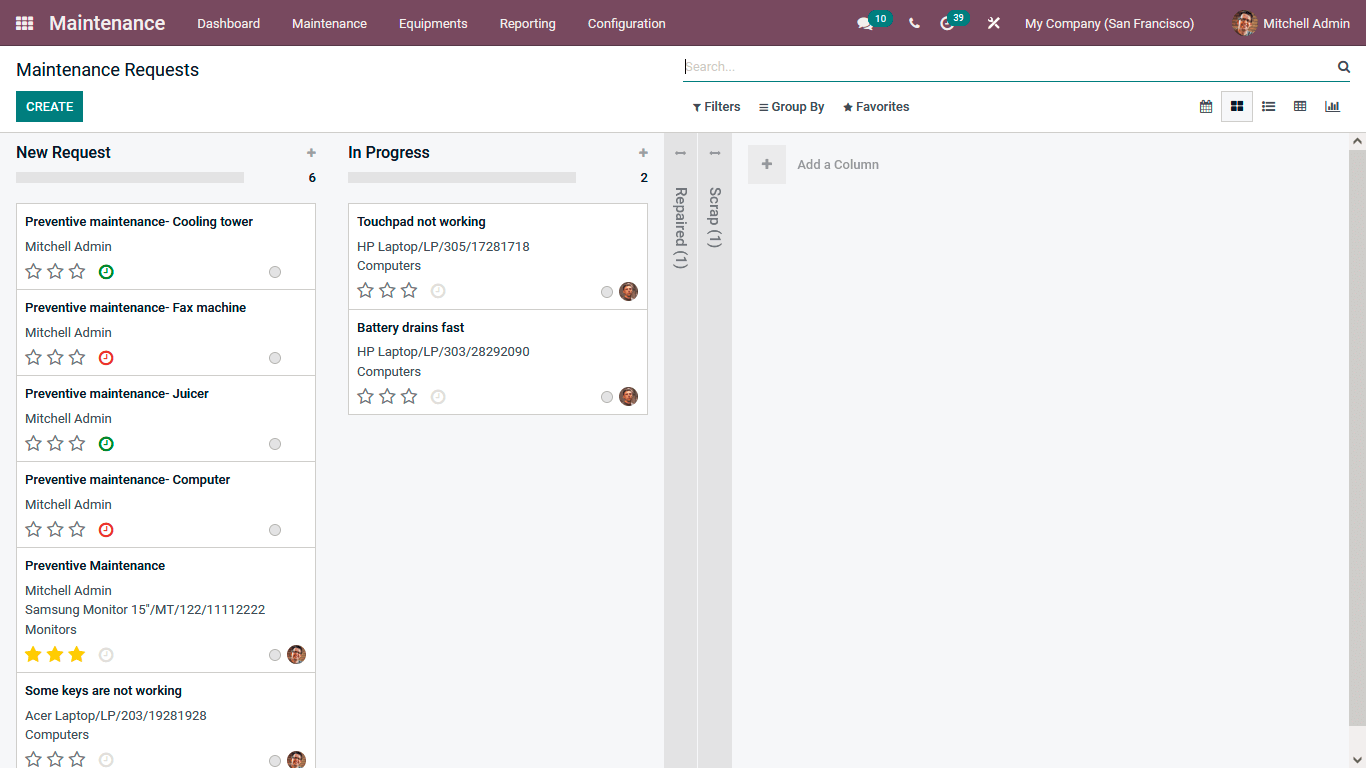

By selecting the Dashboard view of the Maintenance Requests, you will be depicted with the entire Maintenance Requests, which have been defined in the platform as shown in the following screenshot.

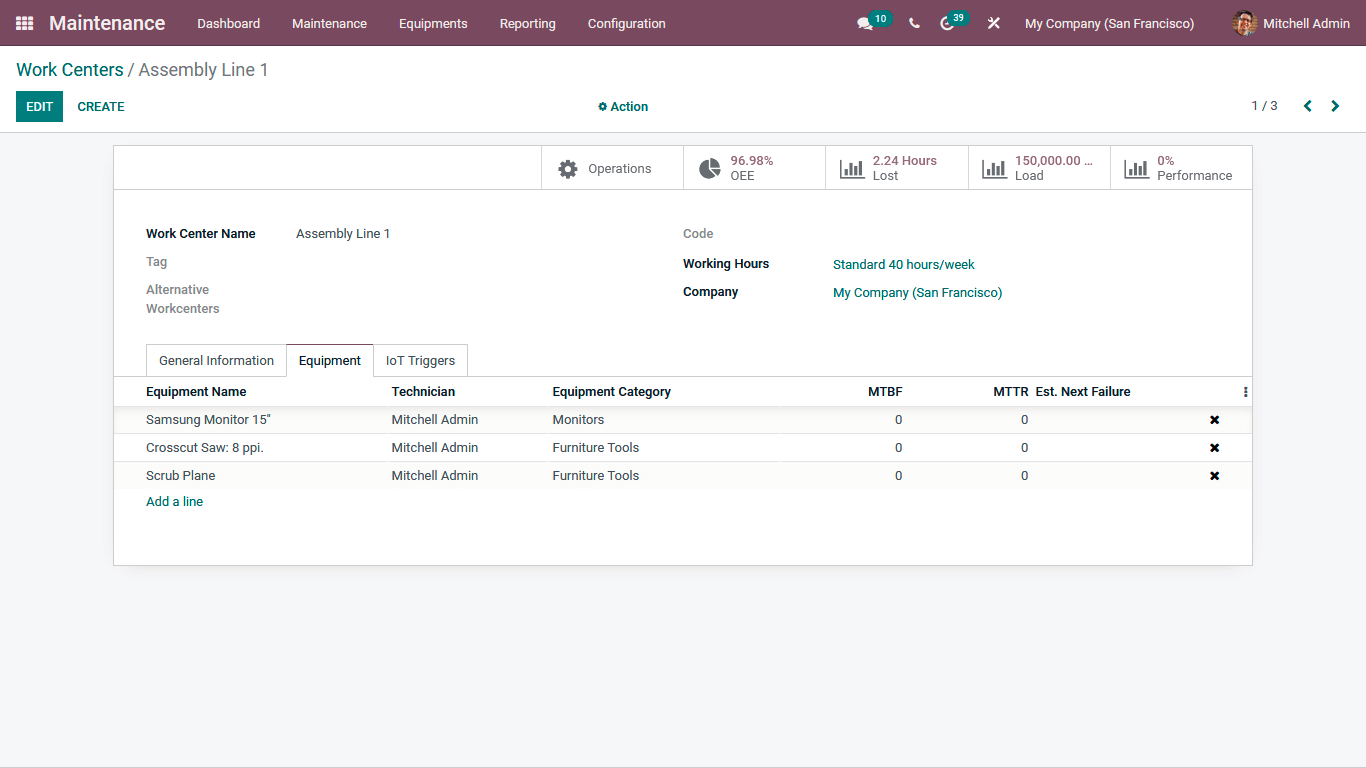

By selecting the Work Centers tab, you will be depicted with the Work Centers in operations in the Odoo platform. Upon choosing a Work center and the Equipment tab defined under it, you can view all the Equipment in process under the Work Center, just as shown in the following screenshot. This will provide an understanding of which all Equipment should be put for Maintenance during the operation of the Work Center.

With the Dedicated functional menus available in the Odoo Maintenance Module, the operations of the Maintenance operations management can be effectively conducted with it.